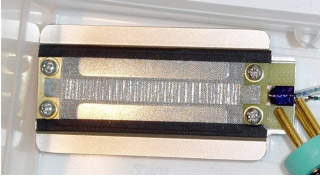

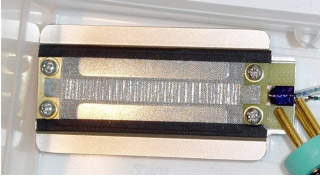

Ribbon mics operate on the same electromagnetic principle as their distant relatives 'dynamic mics' but with one important difference: Instead of the dynamic's cumbersome plastic voice coil (Fig. 1), the ribbon mic employs an extremely thin strip of corrugated aluminum (Fig. 1.3) suspended in a strong magnetic field. Due to its extremely low mass, the ribbon responds to the subtlest variations in sound pressure and moves through space much more freely than the plates of a condenser or the voice coil of a dynamic. Thus ribbons exhibit a natural, even tone that is detailed and musical without the distortion of dynamics or the unnatural brightness of condensers. But low mass also means low electrical output and extremely low impedance: Ribbon microphones require the use of a transformer just before the output to step the voltage up to a useable level, and to raise the impedance from a fraction of an ohm to something more usable (ours are 300 Ohms). The quality of this transformer is critical to the performance of the mic. At Royer, we have not only elevated custom transformer design to an art form in itself, we individually test and grade each transformer before it goes into one of our handcrafted microphones. Active ribbons like the Royer R-122 and SF-24 go one step further and use a FET amplifier stage to increase output and to enable impedance matching. Other active ribbons employ vacuum tube amplifier designs like the Royer R-122V and SF-24V. We were, in fact, the first microphone manufacturer to apply active electronics to ribbons!

Ribbons are traditionally found in recording and broadcast studios due to their exceptional sonic characteristics and proven reliability. In fact, you've heard ribbons on some of the most famous recordings in popular and classical music, and they've been there to report some of the most significant events in modern history. Our award-winning line of live ribbon mics is enjoying its place on stage as well - a place where ribbons aren't usually found. As we'll illustrate below, ribbons offer the recordist and live sound engineer some serious advantages over other designs, and Royer ribbons have established a new benchmark in quality, reliability, and sonic excellence. We didn't invent ribbon mics, but we have taken them to the next level using superior engineering, manufacturing, and quality-assurance processes and the results are nothing short of spectacular. But don't just take our word for it!

Fig. 1.3 - corrugated aluminum ribbon element with damping screen